Career development in welding technology

Allowing your own employees to grow is not only good for the development of the person, it is also good for retaining knowledge in your company. In addition, it is important that everyone has the right competencies. For good craftsmanship. What about your workforce for the future? Elektrolas will be happy to discuss this with you in order to determine which skilled workers you need and which learning path you need to set up.

Lifelong learning and good craftsmanship

Practical welder

A practical welder is active in the workshop. This person enjoys working with different materials, techniques and tools. Practical welder is an umbrella term for basic welder, all-around welder, pipe welder and hygienic welder. A practical welder is result-oriented, independent, physically strong and capable of welding (complex) work of good quality.

Read more about the Basic welder.

Read more about the Allround welder.

Read more about the pipe welder.

Read more about the Hygienic welder.

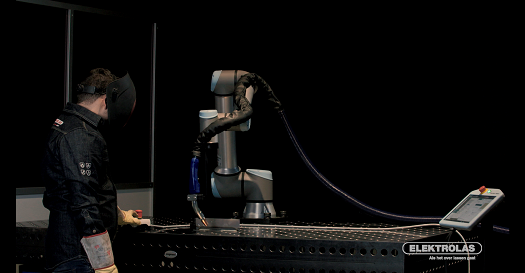

Cobot welder

A cobot welder is a welder with an enthusiasm for automation and someone who enjoys working with both his head and his hands. This person enjoys working with modern equipment and techniques, enjoys programming and performing various welding tasks. A cobot welder is active in the workshop and is able to program on the cobot. He or she is able to estimate which welding jobs are suitable for mechanized execution. The cobot welder is independent, has an affinity for process improvement, is enthusiastic about automation and has welding skills.

Read more about the cobot welder.

Welding coordinator

A welding coordinator is someone with a great deal of welding knowledge. This person draws energy from coordinating welding activities, from preparation to inspection. A welding coordinator is active in the workshop and is part of the quality department and is able to determine the quality of the welding work. A welding coordinator must be both organizationally and communicatively strong. Communicating and instructing personnel, discussions with suppliers, oral and written reporting are important. Accuracy is also required and knowledge of standards.

Read more about the welding coordinator.

Welding inspector

A welding inspector is the expert throughout the project in coordinating and performing independent inspections on all welding activities. This person is capable of preparing quality plans and the inspection and test plan (ITP). A welding inspector works in a staff department, such as the quality department of a company. He or she has current knowledge in the field of welding technology, standards, legislation and welding inspection. Is independent, structured, communicative in word and writing, tactful, correct and also dares to make less pleasant decisions.

Read more about the welding inspector.

Career development in your company

Would you like more information about career development in welding technology or would you just like to spar about what is needed in your company? Please contact our training department at 0416-235036 or lasschool@elektrolas.com. You can also leave your details and we will contact you.

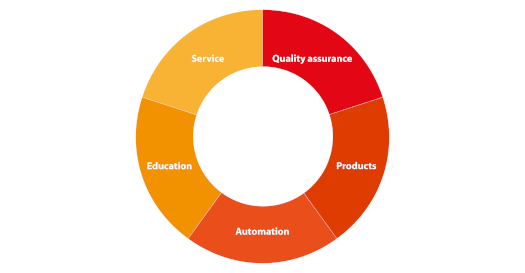

Our Overall Approach - The Disc-Of-Five