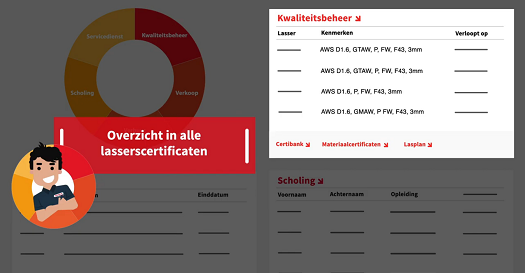

Quality Assurance

Your customers expect an agreed-upon final product quality. What are the benchmarks and minimum requirements for consistent final quality? How do you safeguard the production process and demonstrate the quality of your production to your customers? Elektrolas external welding coordinators (IWTs) support you in this. They set up quality systems, perform visual welding inspections and perform certifications.

In addition, we like to be challenged to think along with you. It does not matter to us whether it is a technical problem or a design challenge. We have the knowledge and experience to advise and support you where necessary in de the process.

Our overall approach

When it comes to welding, Elektrolas has all the knowledge and resources in-house. We are a point of contact for all those involved in the welding process, from tendering to quality control. We are a total provider in the welding field. We secure quality, offer training, sell, rent and service on welding equipment. This is our disc-of-five. Five services that reinforce each other. That is how we ensure that our customers are ready for the future.