Hygienic welder: welding without contamination or corrosion formation

A hygienic welder specializes in making a hygienic (clean) joint on thin-walled food tubes. He must pay great attention to the aspect of safety and hygiene, both his personal safety (protective equipment) and the safety of the installation and the members of the team with whom he may be working. Not only the weld, but also the installation method must comply with the set hygienic and technical conditions. The hygienic welder is mainly employed by and for food and pharmaceutical companies.

What does a hygienic welder do?

The hygienic welder has an executive role. He/she fits and welds stainless steel pipe components in a team or independently. He has the responsibility of constructing and welding a piping section or parts thereof, according to specification. He is aware of his influence on product safety. His personal hygiene and influence on contamination of the product are central to this. The core tasks are:

- Welding of pipe components

- Hygienic installation / construction

- Welding identification / registration

The hygienic welder must take into account limitations of the working conditions, materials to be applied and environment. He does a final check (LMRA) before starting the welding work and reports any deviations that affect the quality of his/her work. The hygienic welder discusses limitations and/or more extensive problems with his/her supervisor or client.

The competences of a hygienic welder

Good workmanship requires that the person possess competencies that determine the job, the profession. A pipe welder should possess:

Responsibility

The hygienic welder is aware of the hygienic and technical requirements of the work and keeping intact the traceability of the materials used and weld produced.

Specialist knowledge.

To be able to lay down a 'clean' weld, the welder must have specialist knowledge and skills. A hygienic weld differs from a normal weld in the requirements for preventing any contamination or corrosion in the weld area.

What is included in the training of a pipe welder?

To be able to grow in the profession and to have the right competences, a learning path has been set out for the pipe welder. This consists of welding training, welding courses and workshops.

- Manual TIG stainless steel pipe training

- Welding certification HDN

- Workshop WPS reading and drafting

- Workshop on reading drawings

Growing in the work develops the talent, craftsmanship increases, appreciation increases, other connections are made and solutions are found faster.

Career opportunities for a hygienic welder

Are you ambitious and do you want to grow within the welding technology. Then there are several positions / professions for which you can learn:

- Welding foreman

- Welding coordinator

- Welding inspector

- Welding engineer

Elektrolas supports operational and managerial staff to take the right steps by providing them with professional training.

Elektrolas advises the right route

By taking a project-based approach to employee training, you can make strategic decisions. We advise you on the long-term direction you can take with your employees and the training you need to achieve that. We have our own welding school in Waalwijk, where we offer all training courses and workshops. This makes the flow of the learning process very smooth. Would you like to talk to us about a training program for cobot welders or do you want to look at your entire workforce together? Contact our Training Department at 0416-235036 or lasschool@elektrolas.com. You can also leave your details and we will contact you.

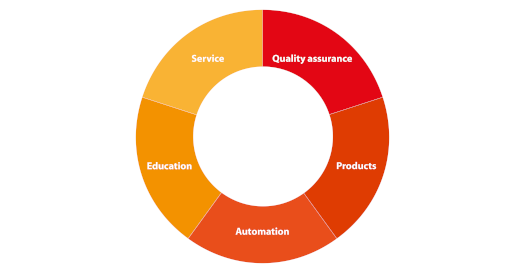

Our Overall Approach

When it comes to welding, elektrolas has all the knowledge and resources in-house. We are a point of contact for all those involved in the welding process, from tendering to quality control. We are a total provider in the welding field. We secure quality, offer training, sell, rent and service on welding equipment. This is our disc-of-five. Five services that reinforce each other. That is how we ensure that our customers are ready for the future.