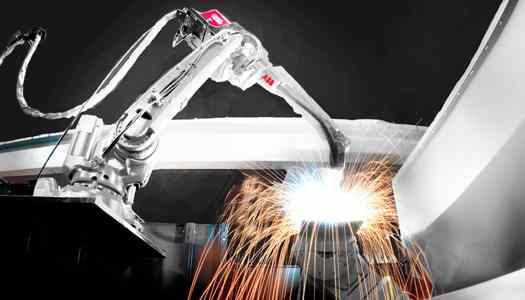

Robotic welding

Welding with a robot. What is a welding robot? What advantages does a robot have? When is it an appropriate time? What can you do with an industrial robot? How do you deploy a robot? Can you do more than welding with a robot?

What is a robot?

A welding robot is an automated system that takes over the tasks of a welder, increasing efficiency and precision. The process usually involves offline programming with opportunities for online corrections. This closed-loop system requires significant investment and annual maintenance. Welding robots operate statically and unidirectionally, making them ideal for repetitive tasks with minimal variability. The technology allows companies to increase productivity while human welders can focus on more complex tasks, creating a win-win situation between automation and craftsmanship.

People also searched for

Elektrolas System Integrator for ABB

After successfully completing dozens of Cobot integration projects in recent years, Elektrolas is also going to help its customers with robotic solutions in the welding shop.

ABB Robitcs and Elektrolas both have the drive to deliver the best technical solution for the manufacturing industry. A driven group of techies who together seek the best solution for every challenge. The cooperation of these ambitious companies is interesting because of the bundled knowledge. Welding and automation are two things that will have a lot to do with each other in the coming years. The Elektrolas training center will also play an important role in the collaboration.

ABB Robitcs and Elektrolas both have the drive to deliver the best technical solution for the manufacturing industry. A driven group of techies who together seek the best solution for every challenge. The cooperation of these ambitious companies is interesting because of the bundled knowledge. Welding and automation are two things that will have a lot to do with each other in the coming years. The Elektrolas training center will also play an important role in the collaboration.

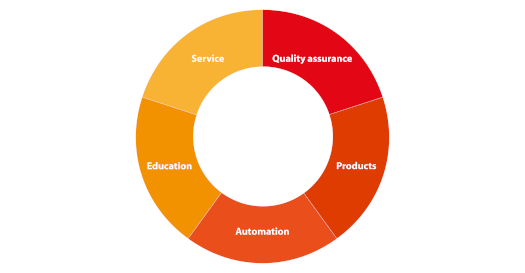

Our Overall Approach

When it comes to welding, Elektrolas has all the knowledge and resources in-house. We are a point of contact for all those involved in the welding process, from tendering to quality control. We are a total provider in the welding field. We secure quality, offer training, sell, rent and service on welding equipment. This is our disc-of-five. Five services that reinforce each other. That is how we ensure that our customers are ready for the future.