Innovations

Developments in the welding industry are rapid, and by making use of those new techniques, you are helping your business move forward. Whether it concerns welding techniques, welding equipment, production resources or systems. Elektrolas is on top of all developments in the market and knows exactly what is needed to make your processes better, smarter and safer.

Laser welding

Laser welding is making inroads in the metal industry. This technique offers a lot of freedom and cannot be compared to traditional welding; it is much faster and more precise. The laser beam can be accurately focused, making very small welds possible.

However, laser technology carries visible and not immediately visible safety risks. In addition, it is a complex process that requires specialised equipment and trained operators.

Read more about laser welding.

However, laser technology carries visible and not immediately visible safety risks. In addition, it is a complex process that requires specialised equipment and trained operators.

Read more about laser welding.

Innovative welding processes

When you choose a welding machine from EWM, you are opting for a technological lead in all welding processes. This means that your welders will get to work with higher efficiency and lower costs, thanks to resource savings. A welding unit from EWM will pay for itself in the long run.

In addition, the welding devices with XQ technology can be connected to digital networks. The software solution EWM Xnet supports, documents and analyses the entire production process from work preparation to post-processing. Completely paperless. This saves time and safeguards quality.

Read more about the XQ welding machines.

In addition, the welding devices with XQ technology can be connected to digital networks. The software solution EWM Xnet supports, documents and analyses the entire production process from work preparation to post-processing. Completely paperless. This saves time and safeguards quality.

Read more about the XQ welding machines.

Robotisation

There is increasing demand for smaller series with high diversity. In addition, it is becoming increasingly difficult to find skilled workers. By automating and robotising, more can be produced with the same number of people. In recent years, Elektrolas has installed dozens of Cobot welding projects in workshops.

In many cases, the goal in these projects is the same: improve production lead times, achieve consistent weld quality and control costs. In almost all cases, we achieve all three. With our welding expertise, we use the cobot to develop the welding solution for your production of tomorrow.

Read more about the cobot.

In many cases, the goal in these projects is the same: improve production lead times, achieve consistent weld quality and control costs. In almost all cases, we achieve all three. With our welding expertise, we use the cobot to develop the welding solution for your production of tomorrow.

Read more about the cobot.

Get in touch

Take the first step towards optimised welding processes and improved business results by contacting us today on 06-25108991 or joost@elektrolas.com. Or leave your details.

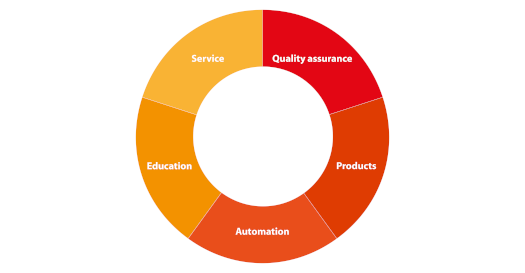

Our overall approach

When it comes to welding, Elektrolas has all the knowledge and resources in-house. We are a point of contact for all those involved in the welding process, from tendering to quality control. We are a total provider in the welding field. We secure quality, offer training, sell, rent and service on welding equipment. This is our disc-of-five. Five services that reinforce each other. That is how we ensure that our customers are ready for the future.