Future of welding: The welding workshop of the future

The welding workshop of tomorrow is a vision. Elektrolas' view on how companies in the manufacturing industry should innovate their welding department to stay competitive. To remain relevant to their customers. Only companies that adapt to market developments will survive. We support those companies in innovating, organizing and automating.

Transitions

How do you prepare your company on its future? We see important developments within the manufacturing industry. There are too few professionals, the demand for ever smaller series and larger variations is rising, production is being brought back to the Netherlands, and the burden of proof and reproducibility are becoming increasingly important. As a result, companies will have to organize, innovate and automate:

- Atomization of work activities

- Improvement of internal processes

- Educating and training of employees

- Demonstration of quality

- Digitalizing of data streams

- flexible deployment of production resources

- a healthy and energy-efficient work environment

Elektrolas has the knowledge, sources and the enthusiasm to look over the shoulders of your organization.

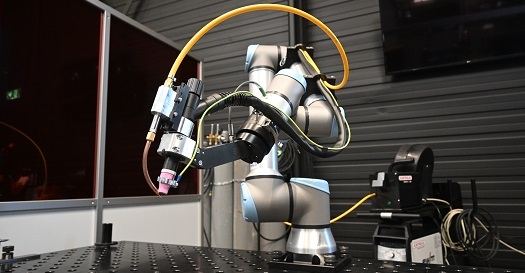

System integration of the cobot or robot

Elektrolas is a certified system integrator of Universal Robots and ABB robotics in the field of cobots and robots. With our knowledge of welding and our experience with automation we will develop the welding solution for your production of tomorrow.

Read more about automation

Technical innovations

Process- and organization improvement

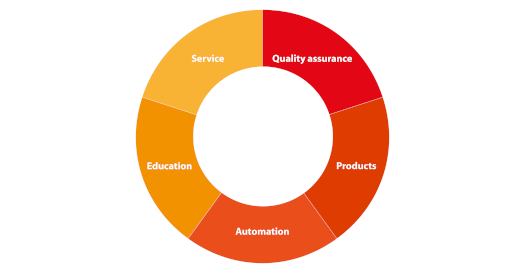

To be able to innovate you often need to organize first. What are your company's ambitions, are the competencies of all those involved in the process clear, are you using the right processes and is there proper communication between the engineering, production and quality control departments. The Elektrolas Welding Improvement Cycle will help you to identify these issues. It is a 4 step cyclus:

1. Good workmanship: preparation of job profiles and competencies.

2. Quality requirements: baseline measurement followed by a customized training plan.

3. Quality Assurance: certifying welders and welding methods, logging of welding data.

4. Improvements: implement innovations in the organization and production process.

Elektrolas will work with your welding department and ensure that you stay ahead of tomorrow's competition.

Read more aboute the Welding improvement project.

What will your future be?

Are you ready for it? As far as Elektrolas is concerned, one thing is certain. Elektrolas is working on the solution that fits you production of tomorrow. Innovate together. Contact us via phone: 0416-336777 or mail info@elektrolas.com. Or leave your information.

Our Overall Approach