Cobot welding: Automation in the welding workplace

There is increasing demand for smaller series with diversity. In addition, it is becoming increasingly difficult to get skilled workers. By automating and robotizing, more can be produced with fewer people. Repetitive welding is taken out of the cobots hands, allowing the welder to focus on specialized welding. The cobot is perfect for making small series and delivers consistent quality. Thanks to Elektrolas’ knowledge of welding technology, we can develop the welding solution for your production of tomorrow.

Flexible use of the cobot

Sanding and polishing are methods that are increasingly common on the cobot. In addition to welding with the cobot. Cutting with the cobot is also often used. This is also increasingly in demand. Together with our partner Universal Robots we are responding to this demand with the UR10e and UR20 cobots. These cobots are capable of polishing, sanding or cutting in addition to welding. Even on one cobot arm.

Sanding: Roughening the surfaces and welds in preparation for surface treatment. With a sanding head on the cobot, this is possible.

Polishing: Polishing after welding is the process of smoothing and refining rough welds by sanding, creating an aesthetically pleasing and glossy finish.

Cutting: With a plasma torch, the cobot can cut holes in desired areas. Couple the cobot with a welding manipulator and pipes can also be cut.

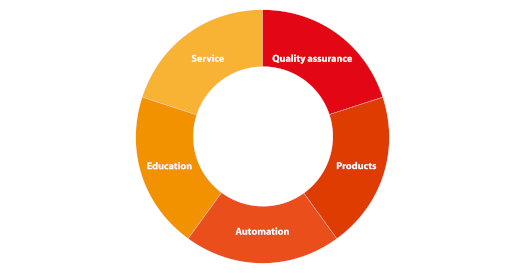

Our Overall Approach