Cobot welder: the go-to person for more efficient production

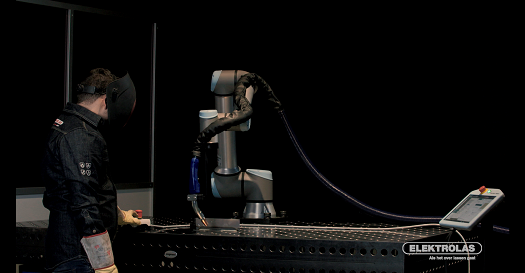

The cobot welder is a welder with enthusiasm for automation and is someone who likes to work with both his head and his hands. This person likes to work with modern equipment and techniques, enjoys programming and performing various welding tasks. The cobot welder can be found in companies that innovate and want to be at the forefront of the market. Being ready for the welding shop of tomorrow. The cobot welder can also be found in industrial companies where welding work is of such a nature that a cobot is used for this. This can include welding work in small series.

What does a cobot welder do?

The cobot welder performs welding with consistent and predictable quality. The goal of the cobot welder is to automate, modernize and make more efficient the welding work in the company. Therefore, this person is active in the workshop and able to program on the cobot. The cobot welder is able to estimate which welding work is suitable to be carried out mechanized. The main activities are:

- Programming the cobot.

- Performing welding work using the cobot.

- Devising and making templates for the cobot.

- Reading and interpreting welding drawings and WPSs.

- Controlling the quality of welding before, during and after production.

- Work according to technical specifications and quality standards.

The cobot welder receives orders from the company office, the cooperating welding foreman and/or workshop manager. The cobot welder reports to the workshop manager or the cooperating welding foreman.

What competencies does a cobot welder have

Good craftsmanship requires that the person has competencies that define the job, the profession. A cobot welder should have:

Independence

A cobot welder is able to perform his welding work independently. Is the initiator for the efficient execution of production within the company. Thinks about automating the work processes himself.

Process improvement

A cobot welder has an affinity for process improvement and looks for new opportunities.

Enthusiasm for automation

A cobot welder enjoys looking at how welding can be done more efficiently and enjoys programming.

Welding knowledge.

A cobot welder has knowledge of welding processes. Because the cobot does the welding, manual dexterity is of less importance compared to a regular welder.

What is part of the training for cobotwelder?

To be able to grow in the profession and to have the right competences, a learning path has been set out for the cobot welder. This consists of welding training, welding courses and workshops.

- MAG skill training level 2

- Training in cobot programming

- Framework training VT-w1

- Drawing workshop

- Workshop Weld Seam Indication

- Workshop making WPS

Growing in one's work develops one's talent, increases one's craftsmanship, increases one's appreciation, makes different connections, and finds solutions more quickly.

Career opportunities for a cobot welder

Are you ambitious and do you want to grow within the welding technology? Then there are several positions / professions for which you can learn:

- Assistant welding foreman

- Welding coordinator

- Welding inspector

- Welding engineer

Elektrolas advises the right route

By taking a project-based approach to employee training, you can make strategic decisions. We advise you on the long-term direction you can take with your employees and the training you need to achieve that. We have our own welding school in Waalwijk, where we offer all training courses and workshops. This makes the flow of the learning process very smooth. Would you like to talk to us about a training program for cobot welders or do you want to look at your entire workforce together? Contact our Training Department at 0416-235036 or lasschool@elektrolas.com. You can also leave your details and we will contact you.

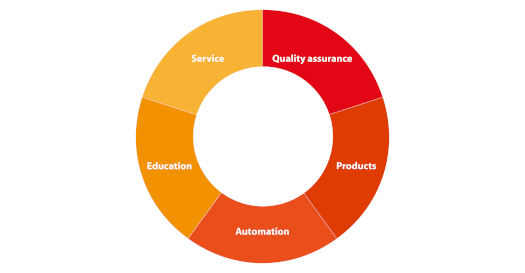

Our Overall Approach