Welding Automation - welding workplace innovations

When to automate your welding workplace

In the time of increasing scarcity of welders and more stingent customer requirements, automation is the key to succes. Implementing advanced technologies such as welding robots, cobots and laser welding automatically increases productivity while ensuring quality. These automated solutions reduce the need for human labor, resulting in consistent results and shorter lead times.

By choosing automation, you give your welding shop the tools to excel in a demanding marketplace. We understand the challenges you face and offer custimized solutions that increase your productivity and meet the most stringent standards.

Welding with a cobot

What is the delivery time of a cobot?

Generally, delivery time can range from a few weeks to a few months, depending on the supplier and any modifications needed.

What does it cost to innovate my welding shop?

The cost of innovating a welding workshop depends on several factors, including the size of the workshop, the type of cobot, any infrastructure modifications and staff training.

Is it possible to visit the COBOT center?

Yes, it is possible to visit the COBOT center. This can be arranged upon request. During the visit, a demonstration can be given to better understand the capabilities and applications of cobots.

When should I deploy a cobot?

A cobot can be ideal in situations where there is repetitive work, a shortage of skilled workers or when the current workforce is limited in size. Cobots can be used to automate tasks and increase productivity in such circumstances

Can you also provide a demonstration?

Yes, this is certainly possible. Please contact us at: demonstration request

Generally, delivery time can range from a few weeks to a few months, depending on the supplier and any modifications needed.

What does it cost to innovate my welding shop?

The cost of innovating a welding workshop depends on several factors, including the size of the workshop, the type of cobot, any infrastructure modifications and staff training.

Is it possible to visit the COBOT center?

Yes, it is possible to visit the COBOT center. This can be arranged upon request. During the visit, a demonstration can be given to better understand the capabilities and applications of cobots.

When should I deploy a cobot?

A cobot can be ideal in situations where there is repetitive work, a shortage of skilled workers or when the current workforce is limited in size. Cobots can be used to automate tasks and increase productivity in such circumstances

Can you also provide a demonstration?

Yes, this is certainly possible. Please contact us at: demonstration request

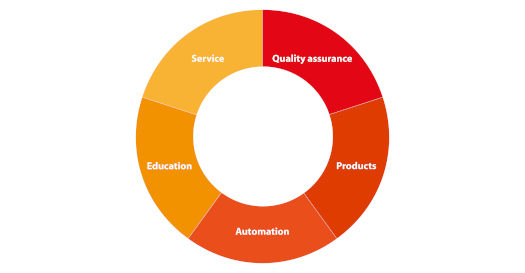

Our Overall Approach

When it comes to welding, elektrolas has all the knowledge and resources in-house. We are a point of contact for all those involved in the welding process, from tendering to quality control. We are a total provider in the welding field. We secure quality, offer training, sell, rent and service on welding equipment. This is our disc-of-five. Five services that reinforce each other. That is how we ensure that our customers are ready for the future.