Welding Coordination RWC

The main task of a welding coordinator is to assess the requirements to be met by a product. This is done in terms of feasibility and weldability. It also checks whether the right welding processes are available. If not, the welding coordinator examines whether these can be obtained in-house or whether the work should be outsourced. In the latter case, he can check whether that company complies with the set (welding) quality requirements for the product to be made.

External welding coordinator

The EU has established CE marking for the manufacture of steel and aluminium structures. Rules for manufacturers in these sectors are laid down in standard EN 1090. If you want to carry out welding work under execution class 2, 3 or 4, you are required to appoint a welding coordinator.

Do you need support for a certain period of time, in the form of coordination or supervision? Then our welding engineers can get to work for you. Get in touch.

Engineering support

An engineer knows a lot about conceiving and designing. When it comes to welding-related standards, our welding engineers can provide information to create a feasible design. This ensures that on the shop floor, weld feasibility is promoted.

We also ensure that you demonstrably comply with welding quality as agreed: traceability of welding documentation. We draw up welding method descriptions (WPS) for the welders and also the welder qualification the welder must meet for that product.

Internal audit

If you have an audit coming up soon or would like to claim a certification that suits your company and you don't have the people or the knowledge in-house, you can let us carry out a pre-scan. Elektrolas has the practitioners in house who can think along with you and your production process methods and advise on improvements where necessary.

Of course, auditing by Elektrolas goes further than just handing out plus and minus points. We also look at improving new welding techniques and processes.

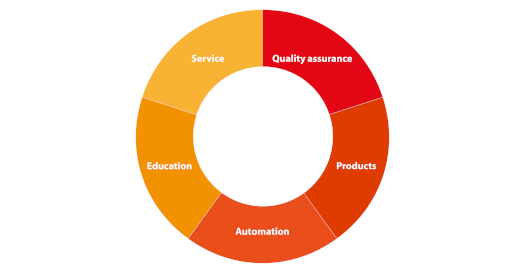

Our overall approach