Certification: securing welding quality

Ensuring welding quality is a crucial aspect within companies where welding is an essential part of the production process. It refers to the process of ensuring and maintaining high standards and norms to ensure that products or processes meet the expectations of customers and other stakeholders. There are several ways to ensure welding quality and make it traceable.

Certify

Do you need certain certifications to be able to take on new assignments or keep permanent ones? Please contact our Quality Management department at 0416-235036. Or let us contact you.

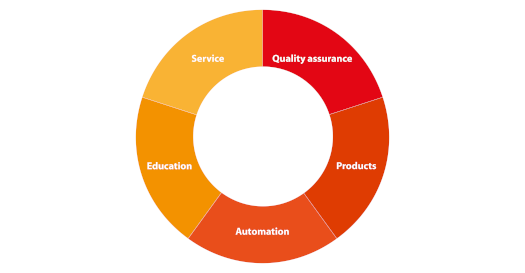

Our overall approach

When it comes to welding, Elektrolas has all the knowledge and resources in-house. We are a point of contact for all those involved in the welding process, from tendering to quality control. We are a total provider in the welding field. We secure quality, offer training, sell, rent and service on welding equipment. This is our disc-of-five. Five services that reinforce each other. That is how we ensure that our customers are ready for the future.