Welding fume control

Welding processes in the metal industry release welding fumes or welding smoke. Welding fumes are a varied mixture of airborne gases, vapors and fine dust particles released from welding and related processes. This mixture depends on the products being welded and the welding process (such as grinding, cutting, sanding, thermal cutting and gouging). Welding fume particles are smaller than 0.001 mm (1 μm) when produced. Over time, however, they become larger as the particles begin to stick together. These particles can then reach a size of 1 to 7 μm.

Welding fumes are released from: the weld pool, filler materials such as electrode and wire, substances on the workpiece such as paint, degreasing media, greases, etc., and surface treatments such as menace, oil and primer.

For help and advice on determining the risks of welding fumes and what measures you can take, contact Elektrolas.

Welding fumes are released from: the weld pool, filler materials such as electrode and wire, substances on the workpiece such as paint, degreasing media, greases, etc., and surface treatments such as menace, oil and primer.

For help and advice on determining the risks of welding fumes and what measures you can take, contact Elektrolas.

Welding fume legislation

The risk inventory and evaluation (RI&E) describes the employer's obligation to assess exposure to welding fumes.

Welding fumes can be considered a mixture of undefined composition within the framework of a risk inventory. This is subject to a legal limit of 1 mg/m3 for an 8-hour workday. The employer is obliged to minimize the release of welding fumes. Without proper measures, this limit value can soon be exceeded.

Welding fumes may contain special components such as metals, for which specific limit values have been established. Especially for welding on stainless steel and duplex, there is a risk that the carcinogenic hexavalent chromium (chromium-VI) may be generated. As a result, the limit value has been lowered to 1 μg/m3.

Welding fumes can be considered a mixture of undefined composition within the framework of a risk inventory. This is subject to a legal limit of 1 mg/m3 for an 8-hour workday. The employer is obliged to minimize the release of welding fumes. Without proper measures, this limit value can soon be exceeded.

Welding fumes may contain special components such as metals, for which specific limit values have been established. Especially for welding on stainless steel and duplex, there is a risk that the carcinogenic hexavalent chromium (chromium-VI) may be generated. As a result, the limit value has been lowered to 1 μg/m3.

Measures against welding fumes

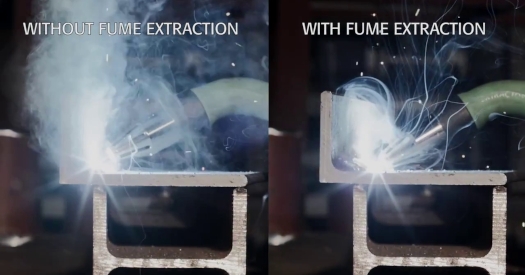

Various measures exist to require exposure to welding fumes. Here one can distinguish between measures at the workplace level and at the workplace level.

Preferably, source measures are used, preventing the release of welding fumes into the (working) atmosphere. This has been proven to be the most effective and efficient method of capturing and removing welding and similar fumes. A welding fume extraction torch is considered one of the better solutions for this. Research has shown that the extraction torch removes 95% of welding fumes, giving the welder a much healthier workplace and protecting his or her health. Also, the welding quality is not altered.

In addition, you can think about spatial control of welding fumes. This involves controlling welding fumes from a central point in the hall, without source extraction. Filter towers can be used.

Finally, personal protective equipment can be used. More below in another chapter.

Preferably, source measures are used, preventing the release of welding fumes into the (working) atmosphere. This has been proven to be the most effective and efficient method of capturing and removing welding and similar fumes. A welding fume extraction torch is considered one of the better solutions for this. Research has shown that the extraction torch removes 95% of welding fumes, giving the welder a much healthier workplace and protecting his or her health. Also, the welding quality is not altered.

In addition, you can think about spatial control of welding fumes. This involves controlling welding fumes from a central point in the hall, without source extraction. Filter towers can be used.

Finally, personal protective equipment can be used. More below in another chapter.

Onze totaalaanpak - De Schijf van Vijf

Alle kennis en middelen rond lasvragen hebben wij in eigen huis. Wij zijn één aanspreekpunt voor alle betrokkenen in het lasproces, van aanbesteding tot kwaliteitscontrole. Elektrolas is een totaalaanbieder op lasgebied. We borgen kwaliteit, geven scholing, innoveren processen, verkopen en verhuren producten en bieden service op lasbenodigdheden.. Dat is onze Schijf van Vijf. Vijf diensten die elkaar versterken. Zo zorgen wij dat onze klanten klaar zijn voor de toekomst.