Welding coordinator course: EWCP-B

Does your company regularly weld in production, repair or assembly activities and do you regularly hire an external welding coordinator for this? Then it may be attractive to train your own experienced welders to become welding coordinators. This gives you an in-house welding coordinator who can oversee the quality standards of various activities at the company and/or welder level.

What does a welding coordinator do?

The main task of a welding coordinator is to assess the requirements that a product must meet. In terms of feasibility and weldability. But a welding coordinator does even more:

- Take stock of whether the correct welding procedures are in place.

- In the case of outsourced work, monitoring whether that company adheres to the set quality requirements.

- Evaluate welding methods and welder qualifications.

- Provide welding method descriptions (WPS) and work instructions.

- Manage certificates of welding consumables.

- Have product traceability in place.

For the manufacture of steel and aluminum structures, the EU has established CE marking. Rules for manufacturers in these sectors are set out in standard EN 1090. If you want to carry out welding activities under execution classes 2, 3 or 4, you are obliged to appoint a welding coordinator.

Who is the welding coordinator course for?

The welding coordinator training course is aimed at experienced welders, welding foremen, quality assurance personnel and inspectors, who want to learn how to supervise welders' and companies' certifications themselves.

The trainee should already have experience in the following material types:

- Type steels S235 - S355 (1.1, 1.2 and 1.4).

- Austenitic stainless steel (8).

In addition, the trainee must demonstrate on their resume that they have at least 4 years of (recent) work experience that is at a higher level than that of a welder. For example, the trainee already has experience in reviewing welds, working drawings, quality requirements, quality documents and in giving work instructions.

What will you cover during the course

- Block 1: Welding processes and welding equipment

- Block 2: Material use and behaviour in welding structures

- Block 3: Construction and design

- Block 4: Quality assurance fabrication and applied engineering

- 3 seminars (introduction EN-1090, tasks and competences of welding coordinator, welding method qualifications according to EN 15614)

Halfway through the course an interim written exam is held. The training course is completed with an oral and written exam.

All exams are under the supervision and responsibility of the Dutch Institute for Welding Technology (NIL).

After this training you will be able to assess whether products meet the applicable quality requirements and you can coordinate the certification of welders and companies.

Subsidy possibilities

There are several possibilities to qualify for an attractive subsidy. You will have to apply for this yourself, but of course we are happy to help you on your way by informing you about the various possibilities.

OOM Foundation

OOM is a training consultancy in the metalworking industry. Their goal is to raise the level of craftsmanship in the metal industry. They do this by stimulating the learning culture within companies. OOM co-finances the training costs for employer, employee or student. Read more about the OOM foundation.

STAP Budget

STAP budget is a personal development budget which you can use to train yourself or to be retrained. It is used to cover (part of) the costs of a training activity. Per year you can do a maximum of 1 STAP course, for which a maximum of 1000 euros STAP budget can be allocated. All our courses, workshops and trainings are eligible for this reimbursement. Read more about the STAP budget.

Welding coordinator training European qualified

This NIL training course has been developed according to the final attainment levels of the European Welding Federation (EWF) guideline EWF 652. This means that the training is European qualified. It is aimed at welding coordination within steel construction, meets the requirements for execution class 2 of EN 1090-2 and has been drawn up in accordance with EN ISO 14731.

Return days and workshops

You must keep the certificate obtained during the welding coordinator training valid. You must be able to demonstrate that you keep your knowledge and skills up to date. To support you in this respect, Elektrolas organizes an annual refresher course.

More information

Our teachers come from the world of practice. In our classrooms, we use state-of-the-art equipment, which means that theory lessons can also be followed digitally at a distance. Are you interested in this training? Contact our Training Department on +31 416 235036. You can also leave your details and we will call you.

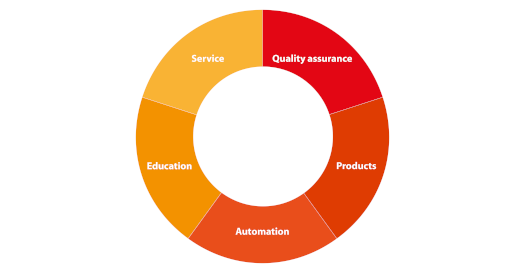

Our overall approach

When it comes to welding, elektrolas has all the knowledge and resources in-house. We are a point of contact for all those involved in the welding process, from tendering to quality control. We are a total provider in the welding field. We secure quality, offer training, sell, rent and service on welding equipment. This is our disc-of-five. Five services that reinforce each other. That is how we ensure that our customers are ready for the future.