Visual welding inspector course: VT

The need for an in-house visual welding inspector is increasing within many companies. Partly due to the European standards that are constantly being tightened. Are you a quality officer, welding coordinator or welding foreman. Then it is essential to also be a visual welding inspector.

Purpose

Increasingly stringent requirements are being imposed on the welding work performed. In order to detect welding defects at an early stage, it is important to carry out a correct visual inspection according to the established procedures. To be able to do that you need to have sufficient knowledge in the field of visual inspection of welding. After completing the Visual Welding Inspector course you will have increased your theoretical and practical knowledge and receive a VTw-1 or VTw-2 certificate.

Intended for

Executing welders, welding foremen, QA/QC staff and inspectors who want to gain more insight into the visual inspection of welding work.

What is the difference between VTw-1 and VTw-2

When choosing to train as a Visual Welding Inspector you have a choice between level 1 and 2. Depending on how you want to apply the knowledge gained after the training you choose level 1 or 2.

After completing the Vtw level / level 1 training you will have become familiar with all the topics and procedures relevant to performing visual inspection, as mentioned in the text block below. You can do inspection under the supervision of a Level 2 Visual Welding Inspector, who evaluates the welding work.

After completing the VTw-2 training you will be able to independently assess welding work. During the training you go deeper into the material than a level 1. Therefore, after the training you can also supervise Level 1 Welding Inspectors. A level 2 Welding Inspector also bears responsibility for the inspection methods chosen.

Contents

During the welding inspector training course, the following topics are covered:

- Principles of visual assessment

- Visual inspection techniques

- Inspection characteristics and applications

- Welding processes and materials

- Reporting

- Inspection during operation, overhaul and maintenance

- Other NDT Techniques

- Safety and certification

As indicated above, the degree of depth and understanding of the material is the difference between VTw-1 and VTw-2. This makes the VTw level 2 training of added value when the trainee wants to supervise welding activities of other welders after training.

Subsidy possibilities

OOM Foundation

OOM is a training consultancy in the metalworking industry. Their goal is to raise the level of craftsmanship in the metal industry. They do this by stimulating the learning culture within companies. OOM co-finances the training costs for employer, employee or student. Read more about the OOM foundation.

STAP Budget

STAP budget is a personal development budget which you can use to train yourself or to be retrained. It is used to cover (part of) the costs of a training activity. Per year you can do a maximum of 1 STAP course, for which a maximum of 1000 euros STAP budget can be allocated. All our courses, workshops and trainings are eligible for this reimbursement. Read more about the STAP budget.

VT certificate European qualified

The training course is completed with a theory and practical exam under the supervision and responsibility of the Netherlands Institute for Welding Technology (NIL). After passing the exam you will receive from us a VTw-1 or a VTw-2 certificate respectively, in accordance with the NEN-EN-ISO 9712. This includes the assessment standards NEN-EN-ISO 10042 and 5817 - aluminum, nickel, steel and stainless steel. The internationally recognized certificate is accredited in accordance with ISO 17024.

Refresher days and workshops

The certificate obtained during the visual welding inspector training course must remain valid. You must be able to prove that you are keeping your knowledge and skills up to date. To support you in this regard, Elektrolas organizes an annual refresher course.

More information

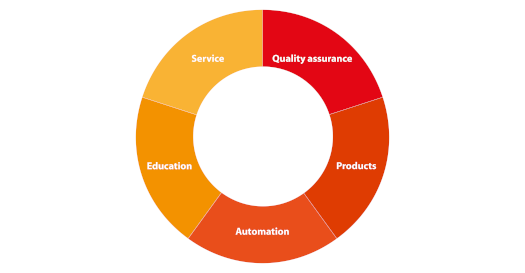

Our overall approach

When it comes to welding, elektrolas has all the knowledge and resources in-house. We are a point of contact for all those involved in the welding process, from tendering to quality control. We are a total provider in the welding field. We secure quality, offer training, sell, rent and service on welding equipment. This is our disc-of-five. Five services that reinforce each other. That is how we ensure that our customers are ready for the future.