Maintenance and repair of oxyfuel

There are no legal requirements or standards for the safe working and storage of oxyfuel equipment. However, the Health and Safety at Work Act states that work equipment that is subject to wear and tear and can give rise to dangerous situations must be tested as often as necessary to ensure a safe situation. This means that the employer is legally responsible for the safety of personnel who, among other things, work with oxyfuel equipment. Elektrolas has therefore drawn up a standard which indicates what is considered necessary to comply with the safe working and storage of oxyfuel tools.

Inspection and testing of oxyfuel tools

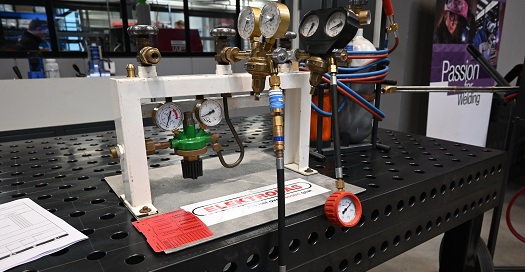

The purpose of regular inspection is to discover defects and to prevent them from occurring after commissioning and causing danger. The inspection that Elektrolas can carry out for you consists of a visual check and a check by measurement. During the visual inspection, the work equipment is critically examined whereby any damage can be determined. It is also possible to determine whether the material has been too hot, usually by means of discoloration. In many cases you can also smell it.

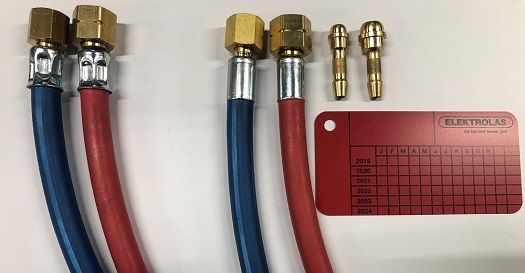

Work equipment that poses a hazard is converted by Elektrolas, in consultation, into safe work equipment. The approved equipment is provided with an Elektrolas inspection label which shows both the date of the inspection and the date of the next inspection.

Safe use of gas hoses

The hoses supplied by Elektrolas are pressed with the safest method. Previously, a collar was pressed onto the sleeve. This can cause unnecessary inconvenience during use. It is also possible that the hose gets damaged internally. By means of the flat pressing no unnecessary hindrance occurs during use and Elektrolas can guarantee that the hose will not be damaged internally.

In addition, Elektrolas only uses hose grommets according to DIN EN 1256. The difference with older types is their length. Because they are shorter, they cannot pierce through the hose when kinking occurs.

Inspection points inspection and maintenance

Reducing valves, burners, welding sets, hoses, couplings and flame arresters must be visually inspected periodically. Elektrolas carries out periodical inspections of regulators on the following points, among others:

- Leak tightness

- Outgoing pressure corresponds with manometers

- Functioning of manometers

- Leakage valve

- Functioning of blow-off

- Hoses and flame arrestors are not older than 5 years

Oxygen and flammable gas valves are equipped with a flame arrestor with three functions:

- Flame arresting sintered metal

- Check valve

- Thermal protection

Maintenance and inspection at your company

Would you like more information about the possibilities for maintenance and inspection of oxyfuel tools at your company? Please contact us on 0416-336777. Or let us contact you.