MIG/MAG welding training level 1 to 4

This welding course teaches you the professional skills of arc welding with melting electrode in shielding gas. After the welding training you should be able to carry out the described and determined skills independently on the basis of the usual drawings and work instructions. The difference between MIG and MAG is in the material being welded. MIG welding is with aluminum, MAG welding is with steel or stainless steel.

MIG/MAG welding training level 1

In terms of content, the following issues are covered:

- Welding processes.

- Welding equipment for MIG/MAG welding.

- Welding of inner and outer corner seams in the position PA and PB.

- Welding of workpieces made of rod, plate, profile and tube materials in the above-mentioned positions. Particular attention is also paid to the selection of the correct parameters and the prevention of faults.

Duration of welding course: 13 or 17 weeks.

MIG/MAG welding training level 2

In terms of content, the following issues are covered:

- Chemistry concepts.

- Iron and steel preparation.

- Cast iron/cast steel and alloying elements.

- The influence of carbon on the properties of steel and its effect on the weldability of steel.

- Trade forms of aluminum and steel products.

- Welding research.

- Welding of inner and outer corner seams, counter welded or not, in the positions PB, PC, PD, PG and PF.

- Welding of V-joints in position PF and V-joints in position PA.

- Welding of workpieces made of and/or composed of rod, plate and profile material in the above positions.

- Welding of internal corner seams in positions PB, PD, PF and PG, external corner seams in positions PB and PD; V-seams in positions PA and PF; I-seams in position PG.

- Welding of workpieces composed of plate in which previously mentioned seam shape, seam forms and welding positions occur.

Duration of welding course: 13 or 17 weeks.

MIG/MAG welding training level 3

In terms of content, the following issues are covered:

- Welding seam forms and pretreatments.

- Loads on structures.

- Shrinkage phenomena.

- Welding positions and welding indications on drawings.

- Reading of drawings.

- Welding of internal and external corner joints, with or without counter-weld, in the positions PA, PB, PC, PD and PF.

- Welding of open V-joints and double V-joints (X-joints) in positions PA and PF.

- Welding of workpieces made of and/or composed of rod, plate, profile and tube material in the above-mentioned positions.

Duration of welding course: 26 or 34 weeks.

MIG/MAG welding training level 4

In terms of content, the following issues are covered:

- Process variables in welding.

- The arc.

- Welding consumables.

- Welding imperfections, causes and occurrences.

- Welding in practice.

- Safety, health, welfare and environment (Arbo).

- Welding of internal corner seams in the positions PD and PF.

- Welding of V-joints and double V-joints in the PE, PF and PC positions.

- Because we work with small groups there is a lot of personal attention and guidance. We use the most modern equipment in our welding school and the lessons are given by experienced teachers.

Duration of welding course: 26 or 34 weeks.

Exams

The welding courses are concluded with a theory and practical exam. These exams are conducted by an independent examiner from the Dutch Institute for Welding Technology (NIL). If you pass, you will receive an NIL diploma. This diploma will always be valid.

Certified NIL Trainer

Elektrolas is registered by the Dutch Institute for Welding Technology (NIL) as an Approved Trainer. This recognition means that with our skills and management training we meet the conditions laid down in the NIL regulations. These include quality control, training plan, materials and experience of our teachers.

Subsidy possibilities

There are several possibilities to qualify for an attractive subsidy. You will have to apply for this yourself, but of course we are happy to help you on your way by informing you about the various possibilities.

OOM Foundation

OOM is a training consultancy in the metalworking industry. Their goal is to raise the level of craftsmanship in the metal industry. They do this by stimulating the learning culture within companies. OOM co-finances the training costs for employer, employee or student. Read more about the OOM foundation.

STAP Budget

STAP budget is a personal development budget which you can use to train yourself or to be retrained. It is used to cover (part of) the costs of a training activity. Per year you can do a maximum of 1 STAP course, for which a maximum of 1000 euros STAP budget can be allocated. All our courses, workshops and trainings are eligible for this reimbursement. Read more about the STAP budget.

Elektrolas Welding School

Because we work with small groups there is a lot of personal attention and guidance. Our welding school uses the latest equipment and lessons are given by experienced teachers. During the training we pay a visit to a destructive testing lab. Here, our students see how the materials they deal with every day are tested.

Are you interested in a welding course? Request more information via our contact form or call our Training department on 0416-235036.

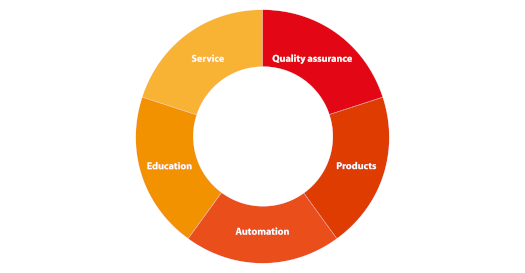

Our overall approach