Hygienic welding training: welding in the food industry

Food safety and hygiene are subject to very high requirements within the food and pharma industries. Many recalls are caused by insufficient attention to the hygienic design of a machine or process installation. The wrong weld can be a source of contamination for the product. As the current certification systems for welders do not meet the specific requirements in hygienic situations, HDN (Hygienic Design Network), in collaboration with the NIL (Dutch Institute for Welding Technology), has developed a uniform method that enables the welder to exclude (unnecessary) contamination.

What is HDN

The HDN platform was created because the Dutch Machinery for the Food Industry (DMFI) sector group felt the need for clarity in the area of European standards and guidelines relating to the design and construction of machinery and process installations in the food industry.

The HDN methodology offers a uniform and simple method to properly and hygienically lay out, register and inspect a weld. It is a procedure and method in which a hygienic weld is defined and made verifiable according to the ISO 22000 standards. Leading companies in the dairy, brewing and sauces industries will work according to the HDN methodology.

Two training opportunities

Elektrolas is an HDN Authorized Education Center for Hygienic Welder. This means that the training can be followed at our location in Waalwijk. HDN has a College of Experts. Elektrolas participates on behalf of all welding instructors to promote the common interests.

To obtain the Hygienic Welder certificate, the welder needs to have a solid level of experience. There are two training options. The certification can be added to the NIL manual TIG level 3 and 4 courses. The level of the welder is determined on the basis of a baseline measurement carried out by Elektrolas. Based on that, a personal training program is tuned.

Welding training Hygienic Welder

The welding certification consists of an introduction to the HDN system and hygienic welding followed by a theory and practical exam.

The training covers:

- HDN Methodology

- Knowledge of materials in stainless steel

- Aspects of hygienic design

- Hygienic processes

- P&ID, ISO metrics

- TIG welding and/or orbital welding

- Welding procedure description (WPS)

- Welding quality / welding criteria

Welding certification takes place in accordance with specific acceptance criteria within the food/feed/pharma industry. The application of the HDN welding registration is a compulsory examination component. The theoretical exam consists of two modules, Hygienic and welding aspects. The practical exam consists of manual TIG or orbital welding of stainless steel pipe joints in 3 welding positions.

Certificate validity

Recognized Training Provider HDN

Elektrolas is registered with the Hygienic Design Network (HDN) as an accredited trainer. This recognition means that we comply with the conditions set by HDN and can guide you through the process of (re)certification of your Hygienic Welder.

Subsidy possibilities

There are several possibilities to qualify for an attractive subsidy. You will have to apply for this yourself, but of course we are happy to help you on your way by informing you about the various possibilities.

OOM Foundation

OOM is a training consultancy in the metalworking industry. Their goal is to raise the level of craftsmanship in the metal industry. They do this by stimulating the learning culture within companies. OOM co-finances the training costs for employer, employee or student. Read more about the OOM foundation.

STAP Budget

STAP budget is a personal development budget which you can use to train yourself or to be retrained. It is used to cover (part of) the costs of a training activity. Per year you can do a maximum of 1 STAP course, for which a maximum of 1000 euros STAP budget can be allocated. All our courses, workshops and trainings are eligible for this reimbursement. Read more about the STAP budget.

Elektrolas Welding School

Because we work with small groups there is a lot of personal attention and guidance. Our welding school uses the latest equipment and lessons are given by experienced teachers. During the training we pay a visit to a destructive testing lab. Here, our students see how the materials they deal with every day are tested.

Are you interested in a welding course? Request more information via our contact form or call our Training department on 0416-235036.

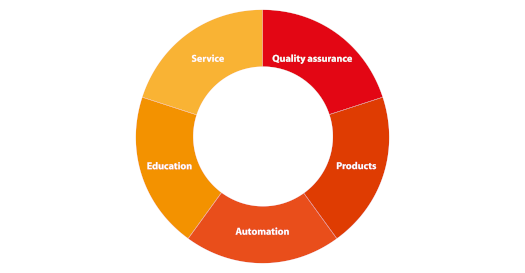

Our overall approach