Welding Procedure Qualification

With a welding procedure qualification, you demonstrate that your welding method achieves the correct mechanical values. Do you have a new welding method in your welding company? Then you need a welding procedure qualification to meet the quality requirements of the welding work. In addition to welder qualifications, Elektrolas can also certify welding procedures. The qualification is carried out according to European and/or American standards.

What is a Welding Procedure Qualification (PQR)?

For a welding procedure qualification, the abbreviation LMK is often used. A welding procedure qualification is a report describing the testing of a specific weld.

The English term is “Procedure Qualification Record”, abbreviated as PQR.

In practice, a welding company often delivers a wide variety of welding work, with different materials welded and various weld seams used. Every welding method must be described, and subsequently, a welding procedure qualification proves that the quality is in order. In many cases, this is also mandatory.

Elektrolas Authorized Organization

The Netherlands Institute of Welding (NIL)

Scope of Elektrolas Welding Procedure Qualifications

Elektrolas can perform welding procedure qualifications under European and American standards. Below you will find the various AWS and ISO standards that fall within Elektrolas’ scope. Contact us and we will gladly tell you more about these standards.

Welding Procedure Qualifications under European Standards:

- NEN-EN-ISO 15614-1 (steel, nickel and its alloys)

- NEN-EN-ISO 15614-2 (aluminum and its alloys)

- NEN-EN-ISO 15613

- NEN-EN-ISO 14555 (stud and bolt welding)

- NEN-EN-ISO 17660-1/2 (welding of reinforcing steel)

Welding Procedure Qualifications under American Standards:

- ASME BPVC.IX

- AWS D1.1/D1.M

- AWS D1.6/1.6M

Why a Welding Procedure Qualification?

A welding procedure qualification is performed to ensure that the quality of the welding work is guaranteed. The welding work must comply with the established standards, for example, NEN-EN-ISO 15614.

By having every welding method in the company qualified, your welding company’s clients know that the quality of the welded work is in order. In Europe and America, welding work must meet strict quality requirements. Elektrolas is authorized to perform welding procedure qualifications for both European and American standards.

With a welding procedure qualification, you thus demonstrate that your welding company possesses the correct welding technical knowledge and skills to weld according to the applicable standards.

Welding Procedure Qualification via Elektrolas: The Benefits

With Elektrolas as your partner, you benefit from the following advantages:

- Elektrolas is an organization authorized by NIL

- Broad scope of European and American standards

- Elektrolas has its own welding school to demonstrably improve your welders’ skills

- Welder certificates can be clearly managed in Certibank

Managing your welding procedure certificates

Elektrolas has developed an online database where we manage your welding procedure certificates. You can consult your company certifications anytime, anywhere. This ensures smooth business operations and safeguards the quality processes of your welding company.

Furthermore, Certibank ensures that your welders always have a valid welding certification. If a welder qualification is about to expire, we will automatically invite you for a welding test. View the benefits of Certibank here.

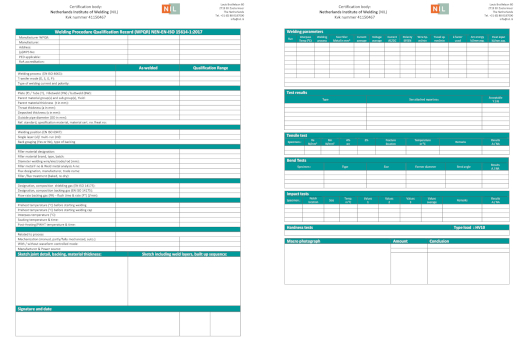

Welding Procedure Qualification Example

- Material data such as strength, type, and thickness

- The welding wire used and the corresponding material certificates

- The type of weld applied

- Test results from various examinations to measure the strength of the joint

- Data on preheating temperature

- And many more details

Meet Rense

We strive daily to help companies in the welding industry work better, smarter, and safer. If you have a question or face a challenge, our welding technicians are ready to assist you. Contact us via 0416-336777 or info@elektrolas.com.