Quality Management: Ensuring Welding Quality

Your clients expect an agreed-upon quality for the final product. What are the criteria and minimum requirements for consistent final quality? How do you safeguard the production process and demonstrate the quality of your production to your clients? Elektrolas’ external welding coordinators (IWTs) support you in this. They establish quality systems, perform welding inspections, and handle certifications.

Additionally, we welcome the challenge of collaborating with you. It does not matter to us whether it concerns a technical problem or a design challenge. We possess the knowledge and experience to advise and support you throughout the process as needed.

Welding Coordination

Elektrolas offers support to companies that have their own welding coordinator, as well as to those that do not. Our welding coordinators can identify potential obstacles during the quotation process and suggest how to prevent them. This helps avoid additional costs or, even worse, subsequent damage. The entire process is documented in writing, ensuring full traceability of how and with what something was produced.

Certifications

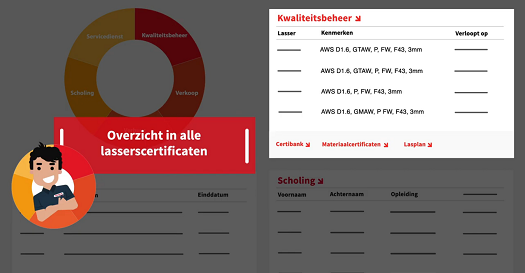

Production according to established quality standards brings efficiency to your operations and is decisive in liability matters. A uniform working method prevents failure costs, disputes, and claims. Elektrolas is authorized by the Netherlands Institute of Welding (NIL) for the qualification of welders and welding procedures. Personal and company certifications are collected in Certibank®. In this database, you can view the competencies of your personnel and receive notifications when welder qualifications expire.

ElektrolasPlan

Engineering, production, and quality control should ideally speak the same language. However, a design that appears workable on paper sometimes proves practically unfeasible. Our independent proactive welding experts (IWTs) offer assistance with the ElektrolasPlan®. They coordinate your project from design to execution and safeguard quality for the future.

Welding Inspection

Welding inspection is an indispensable part of the welding process and plays a crucial role in ensuring the quality and reliability of the welded product. By utilizing various inspection methods and techniques, imperfections, deviations, and potential defects in welded joints can be detected at an early stage. This allows appropriate measures to be taken, ensuring the product meets the required specifications and standards.

Our certified welding inspectors (IWT and VTw-2) can inspect your welding work. They do this according to the standard ISO 5817.

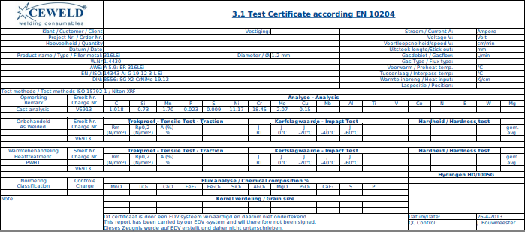

Material Certificates

Material certificates are documents that confirm the quality and properties of materials. They play a crucial role in ensuring the reliability of the materials you use. They serve as proof that the material complies with the required specifications, standards, and regulations. With proper documentation, you can easily demonstrate during an audit that your material meets the required quality.

Certibank

Certibank is an online database that identifies which welding certifications need to be renewed or re-examined, and we schedule these with you in a timely manner. This ensures your welders always possess a valid certificate and quality remains consistent. This allows you to respond immediately to customer inquiries: you can instantly see if you have the right personnel available to produce a specific product.

Meet Rense

We strive daily to help companies in the welding industry work better, smarter, and safer. If you have a question or face a challenge, our welding technicians are ready to assist you. Contact us via 0416-336777 or info@elektrolas.com.