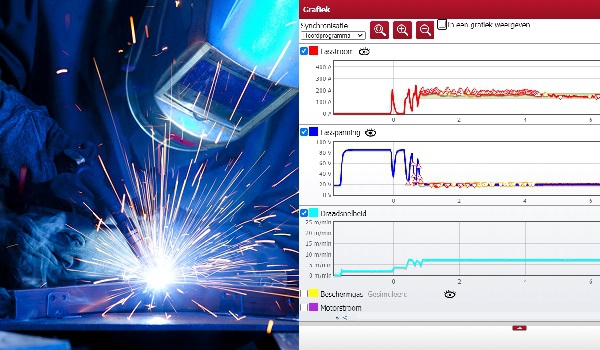

Welding with a welding data management system

You work with a welding data management system to automatically record the actual welding parameters per weld, per product and per project. This allows you to quickly and efficiently build a report for your client. The system is applicable for both large and small companies and supports both the quality manager and the welder in their daily work. It does not matter whether one or more persons are welding at the same time. Each weld is logged by whom, with which machine, with which parameters and on which part of the project. Through this intelligent monitoring and transparent processes of planning, production, quality manager, post-calculation and management, you always maintain an overview.

Digitization of welding

Quality assurance and traceability

What can you do with a welding data management system

Elektrolas believes in the welding management system Xnet, from the high-quality German welding machine manufacturer EWM. This software system consists of:

- Registration of welding data

- Centrally store, view and analyze

- Online monitoring – control and monitoring of welding processes on a desired number of welding machines

- Analysis, assessment, reporting and documentation of online recorded welding parameters

- Transfer capability to all welding devices on the network

- Comfortable and easy to set up graphical layout of all network users

Connecting Welding Devices

The new welding machines are equipped with microprocessors open to data exchange. Multiple welding machines can be interconnected. In addition, the installation of the welding data management system is necessary. This requires a server and a LAN or WIFI connection. During welding, the various welding data are stored directly on the server. In this way, they can be analyzed and evaluated during welding, but also afterwards. Off-line is also possible. Then the welding data is captured and documented on a USB stick.

Maintenance at the right time

To extend the life of a welding machine and keep the quality high, maintenance on the machines is necessary. Through the retrieved data, the optimal time for maintenance and repair work can be determined. That is when a part really needs replacement because it no longer functions.

Meet Rense

We strive daily to help companies in the welding industry work better, smarter, and safer. If you have a question or face a challenge, our welding technicians are ready to assist you. Contact us via 0416-336777 or info@elektrolas.com.